If you are an Engineer or Woodworker you will be fine, you already know that things will go wrong and you have a basic skill set that will enable you to work out the best solutions.

Having said all of that building a clock and getting it running gives a terrific buzz, so the project is well worth working at.

There will be many people coming to this project with some form of CNC machine in the workshop ready to start cutting wood, and that is a good start, but remember there are a lot of components in the clocks that can't be made on a CNC machine, round component, metal components and all manner of purchased items such as screws and pins. So I am going to start this list from the bottom upwards, there is a certain minimum level of equipment that you need to be able to accurately make the clock parts and then to assemble and problem solve the issues that arise.

First the simple basic stuff, hand tools, the picture below shows what you will need to cover all the work that will need to be done by hand.

Most of the tools shown above are fairly obvious, and you probably have them already. Some of the others less obvious, the drill set with drill 1 to 6 mm in 0.1 increments or the imperial equivalent are needed to drill the holes for the shafts and the clearance holes for fitting pins. The reamers are needed to accurately size the holes for the bearings and shafts, I use a 4,6,10 mm reamers

Vernier calliper for accurately measuring, and a small ruler for the same. The Danish oil for finishing of the wood to seal the surfaces and the Dry film lubricant to lubricate the gear teeth and moving parts, grease shouldn't be used

Power tools are probably more commonly available than the hand tools above, so the ones I would normally include as being required for clock building are shown below

You could almost say that the above tools are all that is needed to build a clock, the truth is though you really need something to support the drill in a vertical position for accurately drilling holes. You also need a means of clamping the work piece whilst it is being drilled and for preference some means of adjusting the position of the work piece beneath the drill. To do this you need will need one of the arrangements shown below.

The Drill stand will support the drill vertically and provide a handle to feed the drill bit into the work. The vice on a cross slide is the ideal means of clamping the work piece below the drill to give it both support and adjustment, but you can get away with the simple vice arrangement on the left. The arrangement on the right is from Proxxon looks ideal but may be a bit small.

I have shown the coping saw amongst the hand tools and I guess you could attempt to cut all the clock parts with one of those but it is not really practical. The most common way of cutting the parts would be either to use a Scroll Saw or a CNC router

The saw shown is ideal for cutting the gears and all the other flat parts in a clock and many of the clock builders use a saw like this to do just that. There is an alternative to this and that is to use a small bandsaw as I did for my first clocks, but the scroll saw has more control and hence precision in the cutting.

If you are simply interested in building your clock with the above equipment you need read no further as you have chosen the route that will not break the bank but will still give you great satisfaction but probably a lot harder work.

There a quite a few components in the clocks that are round and not suited to either Scroll saw or CNC routing, so you need to either out source those parts or be creative and change the design to use materials you can work with. Sleeves are on example that are ideally made on the lathe but can be made from dowel in shorter lengths and then drilled, or simply substituted with clear plastic tubing.

The lathe shown above is a small bench top machine ideally suited to the needs of the clock builder.

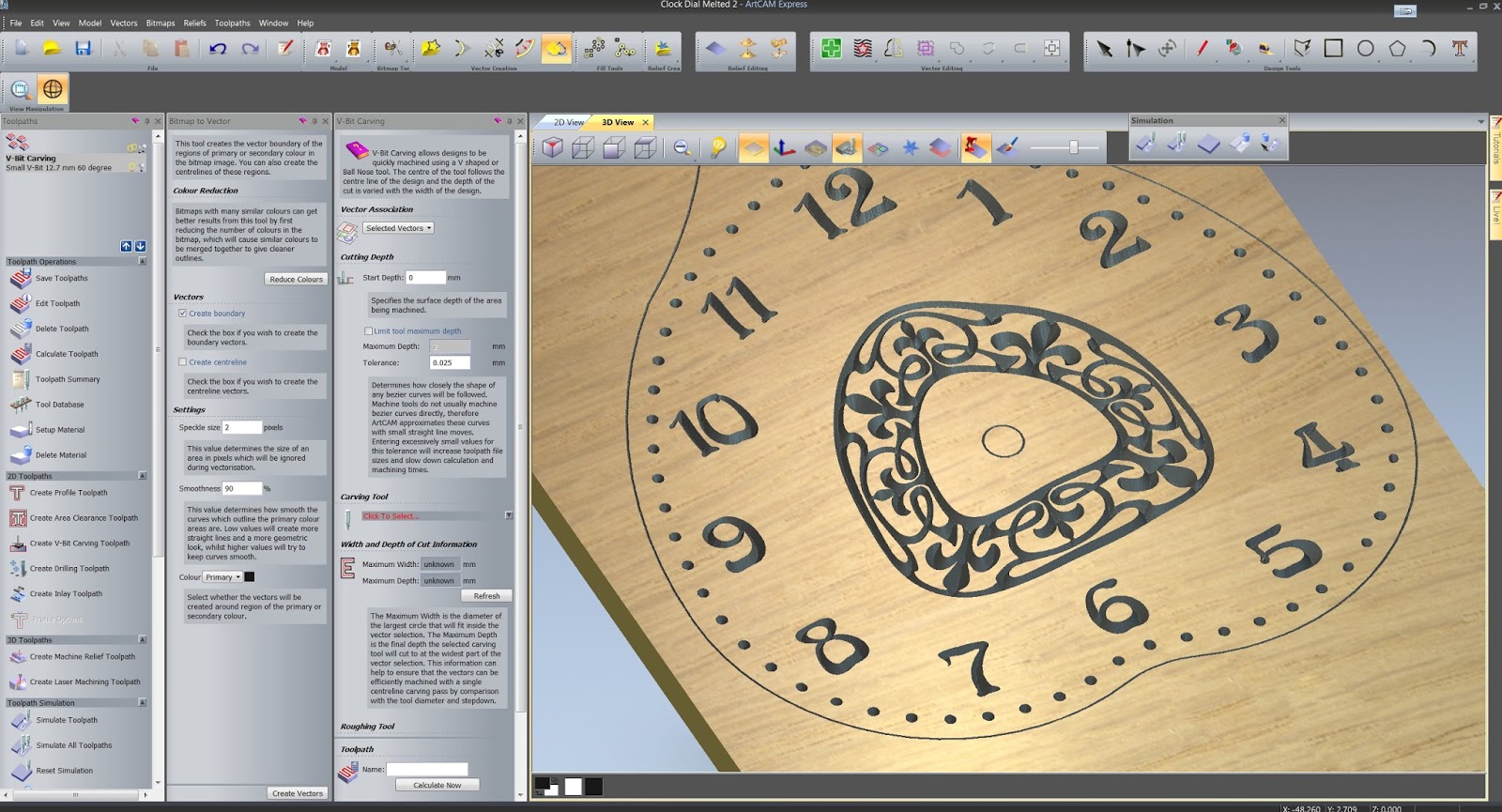

The main alternative to the scroll saw is to use a CNC router or laser, this is a big step up in price to purchase not only the machine but all the software needed to use it.

The software requirement to run a CNC machine is considerable and can be costly if you are to use the mainstream commercial software.

For a start you need a CAD program to make any changes to the DXF files you feel that you want to make, or you may simply want to regroup the gears and profiles to suit the way you are going to cut them.

The Cam software is used to take the DXF files and generate cutting paths for the tools you are going to use to cut out the profiles. It then generates the code necessary to cut the profiles on the CNC router.

The CNC Controller actually connects to your CNC router and feeds the code to the machine.

I am familiar with the software shown above but there are many more free and commercial alternatives that you should look at before you actually buy anything.

DraftSight is a good choice for free CAD software it will do all the changes and manipulations you want to do on the DXF files. If you want 3D capabilities choose one of the other two 'paid for' solutions.

Both Cut2D and Artcam express are simple to use and are relatively inexpensive in this category.

Mach3 is probably the most popular controller, simple to use at a basic level but also with great depth of features if you need them. You will have to pay for this.

I have avoided giving you links to all of these products as you can surf the net as well as I can using the keywords for the items you are interested in. This way you get to choose yourself from the wealth of material out there. However I will make one exception and that is to lead you to this website that has a collection of all the CAD CAM controller software available, mainly free.